STERILISATION

SW- PLATINUM

ONE CYCLE, 100ml OF TAP WATER, UNRIVALLED PERFORMANCE

We developed the first closed-loop steriliser that uses mains water through a specific internal filtration system that recycles water to be reused in the following cycles. This performance eliminates waste, reduces costs and ensures a significant increase in the efficiency of any modern dentistry surgery. It also solves all issues relating to demineralised water storage and supply.

Operating principle

Unlike traditional sterilisers, SW Platinum does not require any external water connection for mains water treatment. Thanks to the demineralisation filter on the main tank, the user can fill the latter with plain tap water, thereby significantly optimising spaces, streamlining processes and achieving considerable savings. The different filtration systems of SW Platinum guarantee unprecedented ease of operation.

Used water treatment

The nano-ceramic recirculation filter, incorporated into the secondary tank, makes it possible to distil and purify water so that it can be reused in the following sterilisation cycle. The built-in conductivity sensor ensures compliance with water quality parameters as it protects the machine internal components from excess lime. Total consumption is 5 litres per 50 cycles, meaning approx. 100 ml/cycle, a real revolution.

7” Display

The size of the display, its performance and the research carried out to develop the user interface make the steriliser simple and ready-to-use. Video tutorials and light indicators turn SW Platinum into a unique steriliser.

SW-17 PLUS SW-22 PLUS SW-28 PLUS

Operating principle

Unlike traditional sterilisers, SW Plus does not require any external water connection for mains water treatment. Thanks to the demineralisation filter on the main tank, the user can fill the latter with plain tap water, thereby significantly optimising spaces, streamlining processes and achieving considerable savings. SW Plus filtration system guarantees unprecedented ease of operation.

E¬fficiency and saving

Never before has a steriliser provided such high performance and low usage costs. Since water is demineralised by SW Plus filter, the user does not need to source demineralised water: they will¬ only have to fill up the machine tank with tap water. Recipients’ storage and deterioration of machine internal components caused by poor water quality will be a thing of the past.

LCD Display

SW Plus is a smart and essential working tool that ensures excellent performance also thanks to the colour LCD touch screen and user-friendly interface. Each check is represented by icons that make it easy to identify current machine status.

SW-17 SW-22 SW-28

LCD Display

The LCD display with keypad features clear user-friendly icons. The operator’s task is made easier and faster thanks to on-display availability of all data. Easy to install, a simple guided procedure aids the initial configuration.

3 volumes, one size

The SW range is available in the 17, 22, and 28-litre versions. Three different capacities to allow users to choose the most suitable machine according to their needs. External dimensions, being the same for the three machines, make installation easier. The 17 and 22 litre models have five trays while the 28-litre model has six.

Water management

The doors on the upper part of the steriliser allow the operator to reach the tanks to fill them with demineralised water and clean them. The in-tank sensor checks water quality and ensures long-lasting machine performance. As an alternative to upper loading, the front quick couplings can be used to empty the tanks and to feed in demineralised water.

TETHYS H10 PLUS

Tethys H10 Plus is the new thermal disinfector that makes the instrument reconditioning process simple and practical. This innovative device carries out many of the numerous manual tasks typically encountered prior to sterilization, thus reducing personnel workloads and risk. With the Tethys H10 Plus decontamination, washing, thermal disinfection and drying are compacted into one fast automated process.

TETHYS

Without doubt, the answer to obtaining the best results with least effort is provided by the latest series of Tethys washer-disinfectors. These completely automatic devices guarantee perfect cleaning of instruments and the highest standard of disinfection, while ensuring at the same time complete protection for operators and the elimination of any possible procedural errors.

There are 45 cm (Tethys T45), and 60 cm (Tethys D60/T60) versions available.

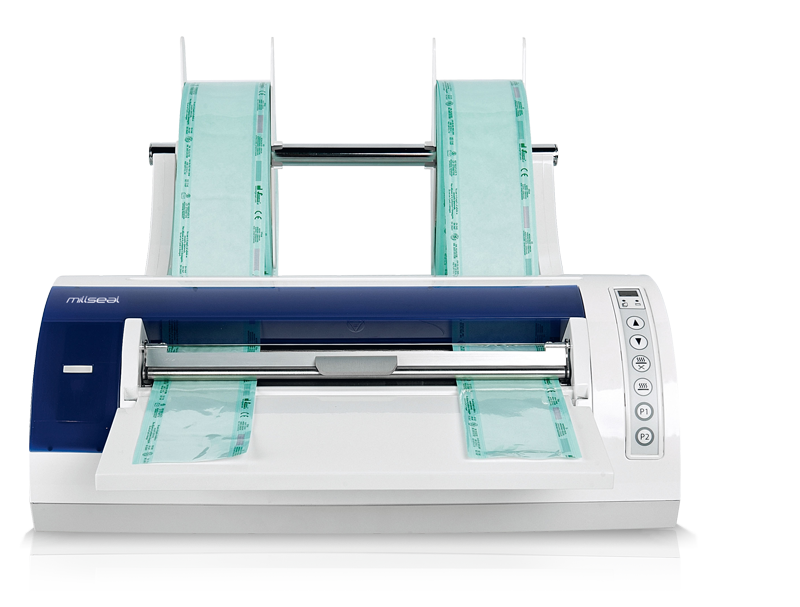

MILLSEAL+ MANUAL

Bag length is selected manually, as is the bag cut. To close the bag containing the material ready for sterilisation just press on the sealing lever until the “sealing complete” beep sounds. A positioning systems holds the paper in place to prevent rewinding of the roll after cutting and sealing.

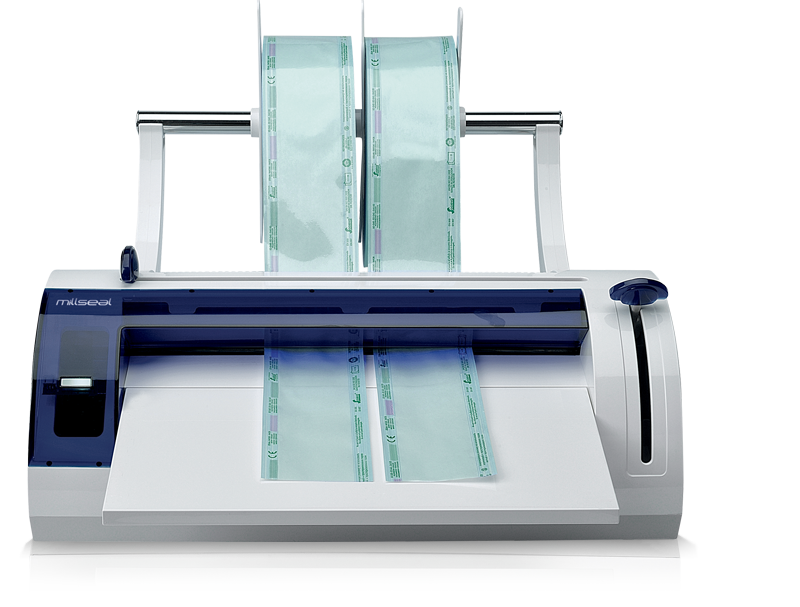

MILLSEAL ROLLING

Roller-type thermal sealer with automatic feed system. Offering medical-standard quality, this unit is ideal for speeding up and optimising sealing of pre-cut bags sealed on 3 sides. A 15 mm sealing band ensures longlasting sterility of bagged instruments. The large display allows the user to view and set working parameters simply and intuitively.

HIGHEA

Simple ultrasound efficiency that strips dirt from the surfaces of the immersed objects, cleaning even those parts that are hardest to reach and the tiniest of holes. Thanks to the heating function the temperature can range from 30 to 80 °C with 5 °C setting steps. LED lights indicate set temperature and current temperature at all times. The Highea ultrasound tank lets you select a wash time from 1 to 30 minutes. It’s also possible to wash continuously for an indefinite time. Available in three sizes (3, 6 e 9 litre).